Defects that arise during the molding of plastic products can have different origins. These may be defects associated with an unsuccessfully selected composition of the plastic (composition defects); defects caused by a violation of the molding technological regime and its incorrect selection (forming defects); as well as defects associated with insufficiently thorough mechanical processing or decoration of already molded products (finishing defects).

Composition defects arise when the recipes are incorrectly selected or low-quality components of composite plastics are used, when their optimal ratio is violated.

Composition defects include:

foreign inclusions - visible foreign inclusions resulting from contamination of the plastic composition or equipment;

reduced mechanical strength that occurs with low or excessive filler content. If the content is low, the filler does not have the proper reinforcing effect; if it is in excess, it is not completely wetted by the polymer;

increased water absorption is the result of an excess amount of hygroscopic fillers.

Molding defects arise due to deficiencies in the design of the mold and molding machines, incorrect selection or violation of the plastic processing regime. Particularly important is compliance with the temperature regime and duration of the molding operation. With deviations from the optimal molding temperature, uneven heating of molds, rapid or slow cooling, destructive processes can occur, significant internal stresses may arise, causing deformation of products, appearance of defects in appearance, and also reducing mechanical strength. The most common molding defects include the following: warping - distortion of the shape of products due to differences in the temperatures of the punch and the mold matrix, removal from the mold of an uncooled (for thermoplastics) or uncured (for thermosets) product, uneven shrinkage of plastic components;

cracks are narrow gaps in products resulting from significant internal stresses due to violation of the molding temperature conditions, as well as excessive moisture in the molding sand;

sinks are voids in products that are formed when foreign gas inclusions or gaseous destruction products enter. Shrinkage cavities occur when individual components of the mixture shrink excessively;

swellings - small or large bulges on the surface that arise as a result of increased moisture content in the molding sand, violation of the molding regime (too fast movement of the core pumping air, low specific pressure, etc.);

chips - depressions on the surface of products that occur due to mechanical damage;

burrs - sharp protrusions along the edge and bottom of the product; technological joints - visible lines of connection (junction) of portions of the casting mass, formed when the mass is overheated and low molding pressure;

streaks - noticeable traces of spreading of plastic in the form of stripes or spots due to different viscosity of the molten molding mixture;

flash (burr) - thickening on the surface of pressed products at the place where the mold is separated due to excess or low fluidity of the press powder;

risks and scratches - the result of processing the surface of the mold with coarse abrasive material or damage by foreigners on the surface of the mold;

sprue protrusion - the remaining sprue on the front surface of the product that has not been removed or cleaned;

ejector marks - protrusions and indentations on the body that appear when an unhardened product is ejected from the mold;

traces from the mold connector - a thickened seam on the surface of the product from the flow of plastic when parts of the mold are not tightly connected;

dullness - spots of reduced gloss that form due to insufficient polishing and lubrication of the mold, low temperature or insufficient exposure during pressing.

Finishing defects may be the result of careless or poor-quality performance of a number of operations to correct molding defects: poor removal of flash, poor polishing of marks, scratches and marks from mold connectors, etc. The introduction of new defects in the case of using flash to clean up and removing marks from the sprue, coarse abrasive materials. Finishing defects also include defects associated with post-technological decoration of products: the use of paint compositions with low adhesion, unclear drawing, displacement of decorative components, peeling of decor, spreading of dye, careless execution of decor, etc. In accordance with the requirements of the standards, product defects are divided into unacceptable and acceptable.

Unacceptable defects are holes, cracks, stains, flash, warping of more than 0.5% of overall dimensions (for pressed products), migration of dye, displacement of the component parts of the design and spreading of dye, distorting the appearance of the product.

Other defects are allowed in products if they do not spoil its appearance and their size (quantity) does not exceed permissible limits.

29. Make a conclusion about the quality of an enameled steel teapot with a single-color enamel coating if it has the following defects:

1. “fish scales”;

2. The cover falls out when tilted at an angle of 60º.

Solution;

To solve the problem, we use GOST 24788 - 2001. Household enameled steel utensils. General technical conditions.

1. “fish scales” - not allowed (p. 6, v. 3, p. 1)

2. “the cover falling out when tilted at an angle of 60º” is not allowed (p. 6, clause 5.3.2.2).

CONCLUSION: according to GOST 24788 - 2001, the enameled steel teapot from the received batch does not meet the requirements of the standard and is not allowed for sale.

34. Make a product description of 3 samples of metal utensils in the following form:

Galvanized buckets - purpose, application, price

Production, purpose and scope of galvanized buckets

As you know, a galvanized bucket is a container used for storing and transporting liquid and bulk materials and substances over short distances. In addition, the buckets are galvanized

can be used for storing various small parts, when loading garbage and during cleaning.

The range of use of all buckets, including galvanized ones, is very wide. Galvanized buckets will serve well when loading solutions, wood and metal shavings and sawdust, gravel, sand: their high strength makes it possible to quickly scoop up materials without using shovels, directly, without scattering them, which is not always possible to do using fragile plastic buckets. They are often used to extinguish fires or as a container for garbage. In Ukraine,

the most popular are

galvanized buckets of 10 liters

, although there are similar buckets of 7 liters, 12 liters, and also

galvanized buckets of 15 liters

.

In the construction field of human activity, a galvanized bucket is simply necessary. Here it is used for transferring and preparing enamels, varnishes, adhesives, finishing solutions and for delivering water. For ease of transportation, it is equipped with a metal shackle that can withstand weight up to 15 kg, and has a durable body that does not change shape. The increased strength and long service life of this utensil is achieved due to the fact that thin sheet metal is used for its manufacture, protected from rust and from the effects of various chemical compounds by a special coating, which distinguishes a galvanized bucket from its functional analogues produced by industry. If we compare them with plastic buckets, the disadvantage of greater weight is more than offset by the fact that they can store a wide range of chemically active substances (solvents, etc.) that do not come into contact with the protected metal, but can change not only the properties , but also the structure of polymers. All of the above is the reason that our contemporaries, who have decided to make repairs in their apartment/house, strive to buy

It is the galvanized buckets, giving them preference over all other utensils with similar functional purposes.

Galvanized bucket

No matter how modernized and modern your homestead may be, there are things that you cannot do without today, just like thirty or forty years ago. One of them is a galvanized bucket, traditionally used for various household needs. But, along with the undeniable advantages, the use of such buckets can cause some harm to health.

Today we will talk about the features of galvanized buckets and whether it is possible to heat water in them. The need to quickly heat a sufficiently large volume of water often arises in dacha conditions.

And many housewives have adapted to using galvanized buckets for these purposes.

But is it possible to do this and will the water heated in this way cause any harm? As you know, galvanized buckets are made of steel, then coated with a thin layer of zinc. When such a bucket is heated, zinc salts fall from its surface into the water, which in the future can lead to quite serious poisoning.

Therefore, such water should never be used for cooking or washing the body. But for household (washing, wet cleaning) and construction (preparation of various solutions) needs, water heated in a galvanized bucket is quite suitable. In addition, although a galvanized bucket can be used to transport water, it is still not worth storing water in it because of the danger of the same zinc salts getting into it.

Therefore, the water brought with the help of such a bucket must be poured as soon as possible into another container, for example, into an enamel or plastic bucket. On sale you can find galvanized buckets with a volume of 9 to 15 liters, both with and without a spout.

Application of buckets

Application area:

The galvanized bucket is a classic item that has found

application

in many industries. This container can be successfully used not only for storing and transporting liquids. A galvanized bucket can easily withstand high temperatures, which is why many housewives heat water in it. It is not afraid of rust and will serve you for many years.

Galvanized buckets 7 liters

, 10 liters, 15 liters and

galvanized buckets 12 liters

, are made by stitching with subsequent sealing of the seams, and the fittings of these dishes are made from metal that has similar characteristics to the original one. Being of high quality, the zinc coating does not crack or peel off. All these characteristics ensure a fairly long service life of such buckets: from three to five years. A source of information

What are the defects of carpets, dry cleaners and laundries?

As a result of use, carpet products significantly lose their original properties and acquire:

a) fatal or difficult to remove defects, which include:

- yellowing or browning of the pile surface of white and light-colored carpets. This defect can occur due to the destruction of optical brighteners over time, as well as “aging” processes (oxidative processes under the influence of light, atmospheric oxygen, etc.), as well as when moisture gets on the carpet, which is accompanied by washing out of the soil of the carpet, tannins and pectin substances (natural dyes) and their migration to the ends of the pile yarn. The defect cannot be repaired;

- the formation of pellets that appear in the initial stage of abrasion of the material.

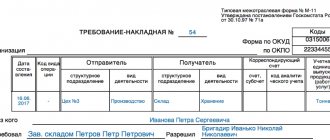

How to draw up an act for writing off materials

In any production one cannot do without writing off material assets. The reasons may be different, but there must always be a documented basis for the process. How is an act drawn up when writing off materials? Production processes are invariably accompanied by user consumption of raw materials and material assets.

Consumed materials must be shown in accounting. That is, the expense must be documented to confirm the write-off. How to properly prepare an act when writing off materials?

It is not only raw materials used for production that are subject to write-off.

Any materials and valuables consumed by the business entity are written off.

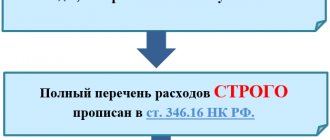

In addition to the fact that confirmation of write-off is important for the reliability of accounting, documentation also plays a huge role for taxation.

When and what to write off and how to formalize it?

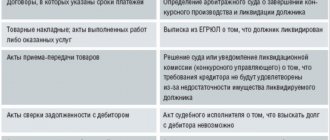

The standard process of writing off materials is carried out once a month. In this case, only those values that are officially accepted for accounting can be written off. The procedure is accompanied by the creation. The amount of materials consumed is determined taking into account the volume indicated in the receipt documentation as an initial indicator. Any consumption of material is confirmed by consumable documents. These data are indicated in the act with reference to supporting documents.

It is also important to take into account natural losses when writing off materials.

For example, individual materials may decrease in volume at or . If normal losses are ignored, over time they can accumulate and become significant, leading to shortages.

Sample act of writing off material assets

The defect will worsen during processing and cannot always be eliminated;

- the presence of stains from blood, paint, ink, mold, animal secretions, protein, oils, fats, fuels and lubricants, fuel oil, glue, medicines, perfumes, red wine, bleach, acids, alkalis that were on the product for a long time during operation, as well as the presence of stains resulting from independent attempts to remove them with chemicals, soap and water. These stains are generally difficult to remove and things with them are accepted without a guarantee of stain removal, and salt etchings are not removed;

- moth etchings, tears, cuts, holes, torn edges, loose hinges, abrasions. The defect cannot be repaired;

- loss or migration of color due to self-removal of stains. The defect cannot be repaired.

- Tears in the frame fabric of the carpet may occur. During operation over time, under the influence of moisture, mold, disinfectant pesticides, unskilled stain removal or washing, traces of cement, tar, glue, the backing frame fabric weakens, and during the cleaning process, tears may form on it;

- undergo shrinkage;

- cracks may form on the latex base of the rugs;

- Peeling of the secondary backing may occur in imported pile-tufted carpets, the reverse side of which, in order to increase strength, dimensional stability and imitate a woven structure, is duplicated with a secondary backing made of jute fabric or fabric containing polypropylene film thread in the warp and jute yarn in the weft. The secondary ground fabric has a loose structure like burlap and is loosely secured along the perimeter of the carpet in the overlock seams, which often leads to its detachment from the overlock seam during the use of the carpet;

- the rubber base of the carpet becomes brittle and begins to crumble;

- a tear in the foam base is formed;

- There may be tears and loss of pile in woolen looped carpets made in China;

- staining may appear on tapestries painted in red or blue tones;

- dye breakage and migration on silk carpets is possible.

c) hidden defects that may appear after dry cleaning:

Describe the defects of plastic products

If the content is low, the filler does not have the proper reinforcing effect; if it is in excess, it is not completely wetted by the polymer; increased water absorption is the result of an excess amount of hygroscopic fillers.

Molding defects arise due to deficiencies in the design of the mold and molding machines, incorrect selection or violation of the plastic processing regime. Particularly important is compliance with the temperature regime and duration of the molding operation. With deviations from the optimal molding temperature, uneven heating of molds, rapid or slow cooling, destructive processes can occur, significant internal stresses may arise, causing deformation of products, appearance of defects in appearance, and also reducing mechanical strength.

The most common molding defects include the following: warping - distortion of the shape of products,

Reasons for writing off furniture.

Types of furniture damage

→ → Update: June 26, 2021

Furniture purchased by an organization for use in public premises (offices, hotels, cafes, shops, doctors' offices, concert halls, etc.) falls into disrepair much more often than its domestic counterparts. As a result of intensive use, individual items may be broken, dirty, the upholstery may be torn, etc.

Information that the organization’s property has fallen into disrepair is recorded in the process of drawing up annual inventory documents or at the time such facts are discovered.

The main reasons for writing off furniture (tables, chairs, etc.)

Inventory accounting Expand the list of categories Subscribe to a special free weekly newsletter to keep abreast of all changes in accounting: Join us on social media. networks: VAT, insurance premiums, simplified tax system 6%, simplified tax system 15%, UTII, personal income tax, penalties We send letters with the main discussions of the week >> Tax-tax January 07, 2021 The reason for writing off a chair, table, cabinet or office chair is the loss of most of the operational characteristics and criteria allowing the further use of the written-off item.

Let's consider the question in more detail. When we talk about furniture, we mostly think about office furniture. Although this could also be the setting of retail or industrial premises, as well as catering premises.

General points for which furniture can be considered unsuitable for further use are:

Methods for writing off materials in construction

When decommissioned, materials must be evaluated. They can be assessed in one of four ways:

- determine the cost of each unit;

- determine the average cost;

- use the FIFO method;

- use the LIFO method.

The chosen method in relation to any group of materials must be specified in the accounting policies of the enterprise and applied during the reporting year.

Estimation at cost of each unit

This method is used in cases:

- when a construction organization has a relatively small range of materials in stock. This allows you to track which specific purchase batch the materials are written off from;

- when materials that are specially registered are subject to write-off;

- if materials were purchased in single quantities for the construction of a specific facility.

Despite the complexity of estimating the cost of each unit, this method is good in that materials are written off at actual cost. However, it requires clear accounting of each purchase. When using this method, you need to know which batch the material is taken from and write it off at the price of this particular purchase.

Average cost estimate

This method contains two options for calculating the cost of material.

Option 1 – weighted assessment:

To determine the weighted score, do the following:

- the cost of a group of materials at the beginning of the month and those purchased before the end of this month is calculated;

- the quantity of materials of the same group for the reporting period is calculated (the sum of the balance at the beginning of the month and the quantity purchased during the month);

- the resulting cost is divided by the amount of materials.

Option 2 – sliding assessment:

The rolling estimate is the actual cost of the material. It differs from a weighted assessment in that when calculating, instead of the quantity of materials purchased during the reporting period, only their receipt at the time of write-off is taken into account (taking into account balances at the beginning of the month).

FIFO method

According to the FIFO method, materials are written off to production in the order in which they were purchased. The batches purchased earlier are written off first. Moreover, written-off (issued) materials are written off at their actual cost, and the balances are valued at the cost of the last purchase. Write-off of materials using the FIFO method can be performed in two ways:

Option 1:

- First of all, the materials of the first batch of materials are written off at their actual cost. If the quantity in this batch does not cover the write-off needs, then the second batch is written off at its actual cost, etc.

- To determine the balance, the cost of written-off materials is subtracted from the total cost of materials received during the month (taking into account the balance at the beginning of the month).

Option 2:

- first, the total cost of materials received during the month is determined (taking into account the balance at the beginning of the month);

- then determine the balance of materials at the end of the month at the price of the last purchased batch;

- the difference between these values will be equal to the cost of materials written off during this period.

LIFO method

This method involves writing off construction costs “from the reverse”: first of all, material is written off from the batch purchased last. Moreover, the cost of written-off materials is estimated at the cost of this batch, and the balance of materials is estimated at the cost of the batch purchased first.

Write-off of open storage materials

Sand, gravel, blocks, crushed stone and other open storage materials are located in open areas. They are spent during the reporting period without documentation. To determine their consumption, a monthly inventory of balances is carried out (at the end of the reporting period). The assessment of inventories spent on production is determined by the formula:

P = N + P – K, where

P – cost of materials spent on production;

N – cost of the initial balance of materials (at the beginning of the month);

P – cost of materials received during the reporting period;

K – the cost of the final balance (at the time of inventory).

Writing off hard-to-recover losses

The consumption of materials in construction includes losses that are almost impossible to eliminate. Hard-to-recover losses can occur when transporting materials from a warehouse or during construction and installation work.

The write-off of these losses is carried out taking into account the standard norms for difficult to eliminate losses given in RDS 82-202-96. If this kind of loss of material resources is not covered by this document, then they should be developed in accordance with SNiP 82-01-85 and the above-mentioned RDS.

Reason for writing off a tool that has become unusable

/ / 03/08/2018 5,029 Views 03/12/2018 03/12/2018 03/12/2018 The act is endorsed by the head of the tool or planning department and submitted to the central tool warehouse (CIS), which issues tools (devices) to the workshop of the same name, brand and size according to the act without issuing claims and limit cards. After the warehouse issues the tools (devices), the act is transferred to the accounting department, where, according to these acts, the tools (devices) are written off from the warehouse, without reflecting their movement through the dispensing storerooms of the workshops. Tools (devices) issued by the warehouse in the order of exchange according to acts are not reflected in the registration cards of distribution pantries.

[3] It is used to formalize the write-off of tools (devices) that have become unusable and exchange them for suitable ones at those enterprises where accounting is carried out using the exchange (working) fund method.

The procedure for writing off plastic containers

Industrial equipment is technical items that are involved in the production process, but cannot be classified as equipment or structures.

Household equipment is office and household items that are not directly used in the production process. The list of property that relates to inventory and household supplies is not established by law. When writing off inventory and utensils, an act must be used (f.

0504143). Regardless of which group of non-financial assets (OS or MH) plastic containers and a culinary hammer are taken into account, the act of write-off of soft and household equipment is used for write-off (f.

0504143). Rationale How to register and reflect household supplies in accounting and taxation The list of property that relates to inventory and household supplies is not established by law. In practice, inventory and household supplies mean: furniture and interior items (tables, chairs, racks, shelves, mirrors, etc.)

P.); equipment for cleaning territories, premises and workplaces (containers, wheelbarrows, buckets, shovels, rakes, mops, brooms, brooms, etc.); lighting, household and other appliances (lamps, scales, clocks, etc.)

P.); fire extinguishing means (hook, bayonet shovel, conical bucket, fire crowbar, felt felt, axe, fire extinguisher, fire cabinet, etc. (except for pumps and mechanical fire escapes)); tools (fitting tools,

Decommissioning sledgehammer

02/21/2019 I.e. There needs to be a compelling reason for an organization to write off the ax from its balance sheet. Please advise, I really need it. An act for writing off the axe. A commission consisting of: foreman Lyapkin A.A., occupational safety engineer Tyapkin O.O., accountant Hapkin U.U.

drawn up this report that the carpenter's ax inventory number 001 has become unusable due to long-term use: there are small cracks and peelings of metal on the butt of the ax, there is a longitudinal crack and significant grooves on the blade, the correction of which is not possible. This ax does not meet safety requirements, as a result of which further operation is not possible. Signatures of the commission members. Well, something like this.

Write the defects more specifically. Source: Act MB-5 is endorsed by the head of the instrumental department, and is submitted to the central instrumental department

Sample act on write-off of soft and household equipment

Approved by Order of the Ministry of Agriculture of Russia dated May 16, 2003 N 750

Agreed by letter of the State Statistics Committee of Russia dated April 10, 2003 N KL-01-21/1381

Form N 421-APK

ACT N _____ FOR WRITTEN OFF INVENTORY AND HOUSEHOLD SUPPLIES ————— ¦ Codes ¦ +————-+ OKUD form ¦ ¦ I approve +————-+ Date (day, month, year) ¦ ¦ ¦ ¦ Manager +—+—-+—-+ ________________ ______________ Organization __________ according to OKPO ¦ ¦ personal signature transcript +————-+ signatures Department (site) ¦ ¦ “__” __________ 200_ +————-+ Farm ¦ ¦ +————-+ Brigade ¦ ¦ ————— —————————————————————— ¦ N ¦Name¦Inven-¦Koli-¦Price ¦Amount, ¦Correspondent- ¦Reason ¦ ¦p/p¦ object ¦tararary¦honest-¦ ¦ rub. ¦account- ¦write-off¦ ¦ ¦ ¦number ¦in ¦ ¦ ¦tov ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +————+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦debit¦credit¦ ¦ +—+——— —+——+——+——+——+——+——+———+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +—+————+——+——+—— +——+——+——+———+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +—+————+——+——+——+——+——+——+ ———+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +—+————+——+——+——+——+——+——+———+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +—+————+——+——+——+——+——+——+———+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ —-+——— —+——+——+——+——+——+——+——— The commission found that the above items had become unsuitable for further use and were subject to write-off. All waste unsuitable for use in production was destroyed in the presence of the commission by __________________ __________________________________________________________________ ___________________________________________________________________ Chairman of the commission ___________ ______________ _________________ position personal signature signature transcript Members of the commission: ___________ ______________ _________________ position personal signature signature transcript ___________ ______________ _________________ position personal signature signature transcript ___________ ______________ _________________ position personal signature decoding of signature Materially responsible person ___________ ______________ _________________ position personal signature decoding of signature Reverse side of form N 421-APK Calculation of results from the liquidation of objects —————————————————————— ¦ Costs of liquidation ¦ Received from liquidation ¦ +————————————+—————————+ ¦ title of documents ¦ articles ¦ amount ¦ title ¦ articles ¦ amount ¦ ¦ ¦ costs ¦ ¦ documents ¦costs ¦ ¦ +———————+——-+——+————+——-+——+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +———————+—— -+——+————+——-+——+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +———————+——-+——+————+——-+— —+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +———————+——-+——+————+——-+——+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ +————— ——+——-+——+————+——-+——+ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ———————-+——-+——+————+ ——-+——- Amount of depreciation ___________________ rub. Results from liquidation __________________________________________ In the card (book) the write-off of property about ___________ Chief Accountant ___________________ ____________________________ personal signature signature transcript

Despite the fairly simple design, during operation of the bayonet shovel it can fail. This may occur due to non-compliance with the requirements for the load on the tool, for example, when developing excessively hard soils, or performing work unusual for a shovel. We list the main damage to a bayonet shovel that can be repaired with your own hands, the causes of these damages, as well as the technology for repairing this tool.

Damage to the wooden part (handle) of the shovel.

This type of damage can occur when digging through very hard soil, such as dried clay.

If you stick a shovel into the ground and try to lift it with the soil, the handle may not hold up and crack or even break.

In this case, you will most likely have to replace the cutting. Using pliers, a screwdriver or wire cutters, we pull out the handle fasteners (the type of tool used depends on how the metal part is secured - a nail or a self-tapping screw). Next, remove the broken part of the handle. If a part remains in the shovel, it can be knocked out with a hammer and a metal pin. As a pin, you can use a piece of reinforcement, a thick screwdriver, or even a piece of a stick or strip a little thinner than the handle of a shovel.

Using a knife or plane, we sharpen a new handle and hammer it into the metal part. At the same time, he must fit tightly into it. It may be necessary to trim the sharpened part a little at an acute angle so that the protruding part of the handle does not rest during work. After this, we fix the metal part to the handle.

This can be done with nails or screws. In the first case, you need to take a thick nail with a cross-section slightly smaller than the diameter of the mounting hole. After this, we cut it off using a grinder, a file or a hacksaw so that the nail with the head becomes 1 - 1.5 cm shorter than the diameter of the handle. Next we hammer it into the hole. If you decide to go with a self-tapping screw, we note that it holds dynamic loads much better.

As a self-tapping screw, it is necessary to select a thick version that is suitable for the diameter of the hole for fastening, and also 1 - 1.5 cm shorter than the diameter of the handle. A roofing screw with a hex key head is perfect for these purposes.

Crack in the metal part.

Due to heavy loads, a crack may occur in the metal part at the junction of the flat part and the fastening part. Such a defect can be partially eliminated using conventional electric welding.

We remove the metal part from the handle and clean the gap or crack from rust. Next, we weld the crack along its entire length, if necessary, aligning the torn parts as closely as possible. The metal on the shovel is quite thick, so a 3 mm thick electrode will be just right. After that, use a grinder to clean the seam. All that remains is to re-attach the shovel to the handle and you can use it. Of course, the shovel will not have the initial strength, but it is easily suitable for loose and loose soils. The only requirement for such a repair is that the metal part must be made of steel.

Deterioration of the cutting properties of the shovel.

Over time, the shovel begins to become dull - this means the cutting edge. As a result, more and more effort is required to drive a shovel into the ground. This can be easily removed with a sharpening machine.

We sharpen the blade like a regular table knife on both sides and the shovel again begins to cut the soil like butter.

If you don't have an electric sharpener, you can do this with a hand-held sharpening stone or file, although in this case it will take a lot more time and effort. The edge must be sharpened to rounding (the vertical edges of the metal part.

Reasons for writing off a galvanized bucket

Contents Utensils made of metal are mainly produced in two ways: the casting method and the plastic deformation method, this is determined by the type of metal or alloy used.

Each method is characterized by certain defects, for this reason they are considered separately. Rodina, T.G. Commodity research of homogeneous groups of non-food products: Textbook for bachelors / L.G.

Eliseeva, T.G. Rodina, A.V. Ryzhakova; Ed. L.G. Eliseeva. - M.: Dashkov and K, 2013. - 930 p. Shells are open or closed cavities in the body of goods.

Causes of early wear of zinc coatings

› Home » Literature » Articles » Author: Corrosion management Most functional coatings are developed to protect the surface of steel under specific operating conditions.

It is on this basis that they are selected by specifiers and end users. To decide on a protective coating, the designer must either trust the supplier to recommend a suitable solution, rely on his own experience with the coating, or have knowledge of the quality of the coating and the environment in which the coating will be placed. The quality of coatings and compliance with standards play an important role in defense projects such as this vessel at Forgac's Dockyard in Newcastle, USA.

All coatings must be updated sooner or later. They are created in order to wear out and protect what is underneath them. If coatings wear out prematurely, the cost of restoration is not commensurate with the cost of initial treatment.

There are many reasons for coating defects.

Some of them are predictable, others are very difficult to determine.

Be that as it may, in most cases the causes of early wear are more likely to be related to human factors than to technology. GALVANIZED COATINGS All galvanized coatings are obtained in