What it is?

Labor productivity, the calculation formula, is an excellent tool that allows you to accurately calculate the efficiency of an enterprise’s use of its labor capital.

This indicator indicates the fruitfulness of the production activities of working personnel, at all levels of management.

A distinctive feature of the calculation formula is the universality of the time factor.

The algorithm is excellent for identifying the coefficient for both one hour and the whole year.

As mentioned above, an indicator is a unique tool for characterizing the performance of employees in calculations for a certain time interval.

For example, you can calculate how many benefits one company specialist can bring in one hour of active work, or, if we are talking about an industrial enterprise, how many parts a worker can produce in eight hours.

The formula for calculating the indicator is based on two fundamental values:

- labor intensity;

- production.

It is these two coefficients that serve as the basis for determining the level of production efficiency of the company and, as a consequence, its profitability. An increase in value leads to a corresponding increase in production volumes, as well as a transition to a policy of greater savings in matters of monthly salary.

Labor productivity is...

Let's start with an example: two turners are working in production, doing the same work. Only one turns 10 parts per day, and the other - 20. These indicators are called production .

Obviously, the output (work efficiency) of the second worker is 2 times higher than that of the first → labor productivity is 2 times higher.

Conclusion: labor productivity of the employee, workshop, etc. – is the amount of products produced per unit of time. This indicator is also called actual PT.

The more products produced per unit of time, the higher labor productivity.

Economics is an exact science; its postulates (what is this?) are based on mathematical calculations.

The reciprocal of labor productivity is called labor intensity (T) . Therefore, this value shows the amount of time spent on producing 1 unit of product. The higher the labor intensity, the lower the PT.

Labor productivity is an important economic indicator. PT, as an indicator of work performance, can be calculated :

- for an individual employee;

- for the enterprise;

- for the industry;

- for the country.

Costing sequence

As mentioned above, the main objective of the formula is to determine how beneficially labor capital is used per a given time interval or the ratio of the volume of the created product and the number of employees involved in its production.

In the process of calculating the indicator, the list number of specialists working in the company is used.

Each individual employee can be counted in the formula no more than once.

Once the number of employees involved in the production process has been calculated, you can add them up by dividing by the number of working days.

It is worth noting that the indicator may well be calculated based on the company's revenue reflected in its financial statements.

Labor productivity - balance calculation formula

In some cases, when an audit of a third-party company is carried out, indirect indicators can be used to calculate the labor ratio, which can be found in a simple accounting report.

Calculation based on the balance sheet does not represent much difficulty and time.

The standard formula is used here. Only instead of the indicator of the volume of products produced (per hour, month, year), the total volume of work performed is used, which is also indicated in the financial statements. Consequently, by dividing the volume of products created over a certain time period by the size of the work performed, one can obtain an accurate calculation of labor productivity.

How to find labor productivity: formulas

To get an answer to the question of how labor productivity is calculated, it is necessary to consider different methods:

- balance sheet calculation;

- profit calculation;

- average daily or average hourly calculation;

- natural method.

Balance calculation

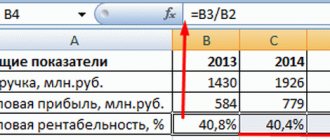

Labor productivity (balance sheet calculation formula) is the most commonly used method.

The formula uses data from the income statement and statistical reporting.

PT = OPP / Count,

Where:

- PT - labor productivity;

- OPP - volume of products produced (financial results report, line 2110 “Revenue”);

- Number - average number of production personnel.

As a result, we obtain the amount of revenue (excluding VAT) per worker. If you link directly to the financial results statement, you can determine the average annual production.

Also, using the specified formula, you can calculate the average hourly, average daily, average monthly output.

Labor productivity by profit

A similar method is used to make calculations based on the organization’s accounting profit.

PT = VP / Count,

Where:

- VP - gross profit (financial performance report, line 2100 “Gross profit (loss)”);

- Number - average number of production personnel.

The resulting value shows how much gross profit falls on one production employee of the organization.

Average daily and average hourly calculation

Average daily or average hourly output shows how much output was produced in a day or hour. It is necessary to divide the volume of goods produced by the number of man-days or man-hours spent on the production of this volume of goods.

PT = P / RV,

Where:

- РВ - working time (man-days or man-hours) spent on production;

- P is the volume of products produced.

Natural calculation formula

The natural method allows you to evaluate the productivity of labor per day (shift) in units of production per worker.

nPT = P / CR,

Where:

- nPT - natural labor productivity;

- KR - the number of workers involved in production;

- P is the number of goods released.

If the resulting NPT value is divided by the number of working hours per day (shift), the result will be efficiency per hour in sales units per employee.

Indicators used

As mentioned above, in the process of calculating the labor productivity coefficient, the labor productivity index, output and labor intensity are used.

Output

The coefficient shows the total size of the product, calculated for a certain time period per one specialist. Output is calculated depending on two factors, namely: the average number of employees involved in the production process and the time spent creating the product.

Liquidity is the ability of some assets to transform into other types of assets. The formula for a company's current ratio will show you its ability to cover its obligations.

You will learn about what an assignment agreement between legal entities is here.

The level of profit from sales shows what level of development the enterprise is at and whether it is worth continuing the current product sales strategy. In this article https://businessmonster.ru/buhuchet/raschetyi/kak-rasschitat-pribyil-ot-prodazh-formula.html you will learn how you can increase your profit and how to calculate it correctly.

Average number of personnel involved

V=Q/B

- Where, V – production;

- B – the average number of specialists involved in production;

- Q – volume of released product or service.

Spent time

V = Q / T

- Where, V – output depending on the time spent;

- T – expenses for working hours to create products;

- Q – volume of released product or service.

In the process of calculating output, downtime is not taken into account.

Labor intensity

The indicator is an accurate reflection of the level of labor expended per employee to create one product.

Represents the inverse coefficient in relation to output.

Average number of workers

H = V / Q

- Where, N – labor intensity based on the average number of employees involved;

- B – number (average) of specialists engaged in production;

- Q – volume of released product or service.

Spent time

H = M / Q

- Where, N – labor intensity per time spent;

- M – funds paid to workers for a certain time (creation of products);

- Q – volume of released product or service.

If there is a need to calculate an indicator based on one worker, then the value of the average list quantity should be equal to one.

It is worth noting that calculating the labor productivity of one employee using a formula per year allows you to most accurately determine the performance of personnel, as well as draw up a detailed plan.

Labor productivity and its essence

An axiom of human existence is the need to satisfy one's needs.

To do this, a person must take a number of actions. Their ultimate goal is to create a certain good. Definition 1

Conscious human activity aimed at creating material or spiritual benefits in order to satisfy one’s needs or obtain a certain benefit (income) is called labor activity or labor.

Labor is not only the most important economic category, but also the main social factor in human development. It influences both the development of production and the formation of the structure and abilities of a person. And the development of society depends on the effectiveness of labor activity.

Help with student work on the topic Average annual and annual labor productivity

Coursework 410 ₽ Essay 270 ₽ Test paper 200 ₽

Get completed work or consultation with a specialist on your educational project Find out the cost

An important characteristic of labor is the indicator of its productivity. Most often it is expressed through the ratio of the level of manufactured products and the level of production costs. Among the costs, special attention is paid to labor costs. Therefore, in economic science there is such a concept as “labor productivity”.

Productivity is the ratio of the amount of output produced to the amount of production input. This indicator determines the cost of manufactured products.

Definition 2

Labor productivity is the ratio of the volume (quantity) of a product produced to the amount of labor expended.

A higher value of this indicator indicates that more product is produced per unit of time. This characteristic is also called fruitfulness or productivity. Its increase indicates a decrease in the level of overall production costs and production costs.

Need advice from a teacher in this subject area? Ask a question to the teacher and get an answer in 15 minutes! Ask a Question

The higher the value of labor productivity, the more products are produced, the higher the value of profit. The consequence of this is an increase in the national wealth of the country and the level of well-being of its citizens. The higher the level of national wealth, the better financed social programs and the entire social sphere of the country in general. And this, in turn, determines the development of social relations and the nature of the political system of society.

Labor productivity characterizes the level of development of the productive forces of a socio-economic formation, the degree of efficiency in using the country's labor, scientific and natural potentials in production. In addition, it indicates labor savings. It is the indicator of saving labor costs and rational use of labor resources (physical and moral qualities of workers) and the search for ways to increase the efficiency of their use that is the main essence of labor productivity.

Formula

Based on the calculation of the specialists’ work results, the labor productivity index is calculated.

The coefficient is an accurate tool for calculating the rate of growth of production results.

The level of labor productivity is calculated using the formula:

- Labor intensity: Δ IN = [(Tro - Trb)/Trb] x 100 percent .

- Output: Δ IN = [(Vo - Vb)/Vb] x 100 percent .

- Where, Vo – produced products for the estimated period of time;

- Vb – production output in the base period;

- Тro – labor intensity of the created product or service for the calculated period of time;

- Trb – labor intensity of the manufactured product for the base time;

- IN - labor productivity index in percentage.

The dynamics of productivity is calculated on the basis of the planned savings in the number of employees. The following formula is used:

Δ IN =[ Eh /( Hr – Eh)] x 100 percent

- Where, Eh – planned savings in the number of employees;

- Hr – the number of specialists involved in the production process.

The calculation for one employee is carried out as follows:

Δ IN = x 100 percent

Formula for calculating labor productivity

Based on the calculation of performance indicators of employees at the enterprise, the labor productivity index .

This indicator reflects the rate of productivity growth and is found as follows:

by production: ΔPT= [(Wo - Wb)/Wb]*100%

by labor intensity: ΔPT=[(Tro - Trb)/Trb]*100%

- where Во – production output in the reporting period;

- Wb – production output in the base period;

- Tro – labor intensity of products in the reporting period;

- Trb – labor intensity of products in the base period;

- PT - labor productivity index in percentage.

The change in productivity can be found through the planned savings in personnel using the following formula:

ΔPT=[Ech/(Chr-Ech)]*100%,

- where Ech is the planned personnel savings;

- Chr – the number of workers (employees involved in the production process).

The indicator of average labor productivity is necessary in the case of a large number of manufactured products with different labor intensity.

Formula for calculating average labor productivity:

Av=ΣQi*Ki,

- where Avr – average labor productivity;

- Qi is the volume of each type of product produced;

- Ki is the labor intensity coefficient of each type of product produced.

To determine this coefficient, a position with minimal labor intensity is selected. It is equal to one.

To find coefficients for other types of products, the labor intensity of each is divided by the minimum labor intensity.

To calculate the labor productivity of one employee, the following formula is used:

PT = (Q*(1 – Kp)) / T1.

To calculate labor productivity indicators, enterprise balance sheet data is used, in particular, the volume of products produced. This indicator is reflected in the second section of the documentation in line 2130.

The formula for calculating labor productivity by balance is as follows:

PT = (line 2130*(1 – Kp)) / (T1*H).

Example

For an example of the practical use of labor productivity, it is worth considering the following situation.

Task

The enterprise manager is given the task of determining to what extent the labor productivity coefficient can change in the planning period, provided that during the reporting time period, products totaling 2.5 million rubles were created.

The number of employees involved is 1,350 people. In the calculation period, if there are no changes in the number of workers, the total volume of product created should increase by six percent.

Solution

The calculation is made based on changes in production levels.

Per employee, the coefficient will be:

B = Q / N = 2500 / 1350 = 1.85 thousand rubles / person

Provided that the volume of the created product increases by six percent, it will be equal to 2.650 million rubles.

If the total number of employees involved in the production process is maintained, the output indicator will be equal to: Вп = 2650 / 1350 = 1.96 thousand rubles / person

Labor productivity growth (according to the formula) is:

∆B = 1.96 – 1.85 = 0.11 thousand rubles or six percent.

Labor intensity makes it possible to determine the maximum level of productivity and, based on these values, the production process can be optimized. Labor intensity: formula and example of calculation, as well as practical application of the obtained indicators.

You will find the profitability formula for core activities in this block.

Balance calculation

Another calculation method is to calculate labor productivity using a balance sheet. To do this, the entire volume of work performed, indicated in the balance sheet, is divided by the average number of personnel, also taken from the reporting. The result obtained will be the actual productivity, reflecting the activities of the entire production or a specific company.

To improve the efficiency indicators of the production process of an organization or enterprise, such a calculation based on the existing balance should be carried out by any manager in order to fully monitor performance and improve net profit and profitability indicators.