Knowing, applying and actually organizing various types of labor safety briefings in the organization, you constantly increase the level of knowledge of workers, their professionalism in terms of their own safety in the process of work, as well as colleagues.

And the more your employees are aware of labor safety rules, the less often you have accidents at work, the fewer fines from the labor inspectorate, higher organization or customer.

And you know the reason, you understand the essence. That is why it is so important to understand and know all types of briefings, promptly monitoring the implementation of each. After reading the article, provide your own examples from practice, ask questions, and we will discuss.

Concept of labor protection

Occupational safety is a set of rules of behavior, measures and special events, the purpose of which is to preserve the health and life of employees. The employer is obliged to ensure labor protection in accordance with legislative acts, ranging from the Labor Code to local documents. There are no exceptions: an organization that does not take care of the safety of its employees is breaking the law.

Occupational safety (OS) is a complex of the following elements:

- industrial sanitation, that is, the reduction and prevention of damage to health in hazardous industries;

- electrical safety;

- fire safety;

- occupational hygiene, that is, preventive measures that prevent or reduce harm to the employee;

- life safety;

- occupational safety management.

All organizations are required to ensure occupational safety: this function can be performed by a manager or an individual specialist.

Conducting briefings with employees is part of occupational safety management. The employer, for its part, is obliged to create the most comfortable conditions for employees, and they, in turn, must know and follow all the rules. Thus, OT manifests itself as an interaction between two stakeholders. Workers avoid injuries and stay healthy, and the organization maintains a healthy workforce, saves on insurance payments and lawsuits, and avoids claims from regulatory authorities.

If an accident occurs at an enterprise, a protocol must be drawn up. Based on this document, regulatory authorities decide whether the employer has fulfilled its labor protection obligations, including whether it has provided instructions.

List of basic documents on labor protection

SCROLL

BASIC DOCUMENTS ON OCCUPATIONAL SAFETY

1. Order on the organization of labor protection and the implementation of a labor protection management system.

2. Regulations on the organization of work on labor protection (job responsibilities on labor protection).

3. Accident log.

4. Register of occupational diseases.

5. Order on buildings, structures, premises.

6. Instructions for the technical operation of buildings and structures.

7. Log of technical operation of the building.

8. Building inspection report.

9. List of works with increased danger.

10. Order on the appointment of responsible persons for the safe performance of loading, unloading and storage operations.

11. Procedure for identifying hazards, assessing risks and opportunities, and determining control measures.

12. Hazard and risk maps.

13. Instructions on monitoring compliance with labor protection requirements.

14. Journal of daily monitoring of compliance with labor protection requirements.

15. Journal of monthly monitoring of compliance with labor protection requirements.

16. Report of quarterly monitoring of compliance with labor protection requirements.

17. Order to monitor the condition of drivers.

18. List of professions (positions) of workers subject to mandatory periodic medical examinations.

19. List of employees subject to mandatory periodic medical examinations.

20. Sending the employer (employer) for a medical examination.

21. Order on examination of workers.

22. Employee inspection log.

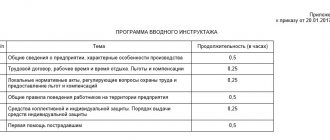

23. Program (instructions) for introductory training on labor protection.

24. Logbook for introductory briefing on labor protection.

25. List of instructions on labor protection.

26. Instructions on labor protection for professions and types of work (services).

27. Logbook for issuing labor safety instructions.

28. Initial training program at the workplace.

29. Logbook of labor safety briefings.

30. List of employee positions exempt from initial workplace and repeated instruction on labor protection.

31. Training program on occupational safety issues.

32. List of positions and professions of workers who must undergo training and knowledge testing on labor protection issues.

33. Order on internship.

34. Order on the creation of a commission to test the knowledge of workers on labor protection issues.

35. Tickets for testing knowledge on labor protection issues.

36. Protocol for testing knowledge on labor protection issues.

37. Occupational safety certificate.

38. Journal of registration and accounting of the issuance of occupational safety certificates.

39. Labor protection action plan.

40. Certificate of acceptance of occupational safety measures.

41. Standards for free provision of personal protective equipment to workers.

42. List of personal protective equipment that directly ensures labor safety.

43. List of professions and positions of workers who are provided with flushing and neutralizing agents.

44. Regulations on the commission for quality control of personal protective equipment.

45. Logbook for recording the results of quality control of personal protective equipment.

46. Personal personal protective equipment registration card.

47. Order on the appointment of persons responsible for fire safety.

48. General facility instructions on fire safety measures.

49. Order on the creation of a training system for fire safety requirements.

50. Introductory fire safety training program.

51. Primary fire safety training program.

52. Fire safety briefing log.

53. Certificates of completion of training under the fire-technical minimum program.

54. Logbook of training under the fire-technical minimum program.

55. Order on the creation of a fire-technical commission and a voluntary fire brigade.

56. Logbook for accounting and maintenance of fire extinguishers.

57. Order on the appointment of a person responsible for electrical equipment.

58. List of positions and professions of workers requiring assignment to electrical safety groups.

59. Logbook of assignment (confirmation) to electrical personnel of the electrical safety group.

60. The act of removing an employee from work for appearing at work in a state of intoxication.

Note

– The above list can be clarified and supplemented depending on the staffing table, types of activities (work) and other aspects of the organization.

Types of occupational safety briefings

In practice, safety instructions alone are not enough to inform workers about all the rules of behavior and handling of equipment. Therefore, there are different types of instructions. from each other in time, repetition and content.

All such subtleties are understood either by the head of the organization (if we are talking about a small organization) or by an OT engineer. This employee is familiar with all legislative acts, necessary rules, and complies with the procedure and timing of mandatory events. Developing briefings in terms of content is also his responsibility.

In addition to educating the state about TB, knowledge testing is a good solution. That is, the engineer first gives a lecture to employees about safety precautions, teaches how to operate the equipment, and then tests whether the material has been mastered. The employee confirms knowledge by signing the logs.

Introductory

The very first briefing given to employees is called induction. It is organized on the very first working day, during the signing of the employment contract. Mandatory for all people applying for work. The introductory training session is conducted by a manager, engineer or HR specialist. The new employee is introduced to the basic safety rules of the organization. Their list depends on the specifics of the enterprise’s activities. Approximate content:

- legislative acts and local regulations on labor protection;

- rules of behavior at work and during emergency situations;

- information on personal protective equipment (PPE).

For example, in “safe” organizations, instruction is limited to studying the evacuation plan and the rules for using electrical equipment. In industrial production, induction training is more complex, but still not too voluminous. Its task is to introduce the basic rules of behavior on ordinary days and in emergency situations, without delving into the specifics of the work. Special subtleties and details are contained in the initial instructions.

Types of briefings vary in timing, content and frequency

Primary

Primary instruction in content is related to the profession and the specifics of the enterprise. It is passed by everyone whose work poses a risk of injury or harm to health during the performance of work duties. Accordingly, the content of the training will vary. Approximate content:

- familiarization with the technological process at the work site;

- rules for using equipment;

- workplace preparation rules;

- requirements for condition, appearance, use of PPE;

- first aid;

- liability for violation of safety rules.

The content is developed and approved on site, taking into account its own specifics. For example, in medical organizations, a new employee will be introduced not only to the general rules of conduct, but also to the procedure for storing medicines and potent medications. The safety instructions for a pharmacist in a pharmacy will be similar, since this specialist’s responsibilities include the sale and storage of substances whose circulation is restricted by law.

An engineer or a specially appointed employee has the right to organize initial training. For example, the head of a department or a workshop foreman. The authority of an official must be confirmed by a special order or regulation.

Repeated

Repeated instruction is carried out to refresh and consolidate information. His task is to re-inform employees about safety rules, and also to make sure that employees remember all the rules and comply with them. Usually carried out every 6 months, that is, twice a year. But for workers servicing dangerous equipment, more often - every 3 months.

The regularity of repeated briefings and the list of employees required to participate in it must be approved by a separate order.

This is an optional procedure. For example, if a person's activity does not involve hazards, re-instruction is not carried out. Its content also does not need to be worked out separately; it duplicates the primary one.

Unscheduled

Sometimes unforeseen situations happen in enterprises. For example, the production order changes or new equipment arrives. To ensure labor safety in the updated conditions, unscheduled instruction is required. Its task is to introduce employees to the changes and teach them how to work safely in a new environment.

Situations when unscheduled instruction is necessary:

- new equipment, the operating technology of which differs from that previously used;

- when new legislation comes into force;

- after an accident or a requirement from regulatory authorities;

- after a break in work of 1 month;

- by decision of the manager.

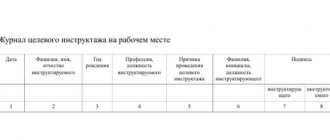

Target

The meaning of targeted instruction is clear from its name. It is carried out when it is necessary to inform about the rules of behavior in a specific situation or at a specific point in time. It differs from unscheduled in that, as a rule, it is known in advance or its content covers only a specific issue and does not duplicate the primary and repeated procedures. For example, safety training in the winter - its necessity is known in advance, and the content is subordinated to informing about the procedure for working in cold and icy conditions.

Situations when targeted instruction is carried out:

- one-time atypical work for employees;

- elimination of accidents, fires, floods and other natural disasters;

- before public events;

- briefing before the route;

- before being allowed to work with a special permit.

Employees who have completed the training must sign in a special journal

Enterprise safety

Purpose: To become familiar with and study safety precautions at the enterprise and during installation work.

Progress:

1. Familiarize yourself with the safety rules

2. Make a note on general safety requirements in production, special safety requirements and safety requirements during installation work.

3. Answer the teacher’s questions.

Safety precautions

Safety precautions mean a set of technical and organizational measures aimed at creating safe working conditions and preventing accidents at work.

At any enterprise, measures are taken to ensure that the work of workers is safe, and large funds are allocated to achieve these goals. Factories have a special safety service, subordinate to the chief engineer of the plant, which develops measures that should provide the worker with safe working conditions, monitors the state of safety precautions in production and ensures that all workers entering the enterprise are trained in safe work practices.

Factories systematically take measures to reduce injuries and eliminate the possibility of accidents. These activities boil down mainly to the following:

- improving the design of existing equipment in order to protect workers from injury;

- installation of new and improvement of the design of existing protective devices for machines, machines and heating installations, eliminating

- improving working conditions: ensuring sufficient lighting, good ventilation, dust extraction from processing areas, timely removal of production waste, maintaining normal temperature in workshops, workplaces and heat-emitting units;

- eliminating the possibility of accidents during equipment operation, rupture of grinding wheels, breakdown of rapidly rotating circular saws, splashing of acids, explosion of vessels and lines operating under high pressure, emission of flame or molten metals and salts from heating devices, sudden switching on of electrical installations, electric shock, etc. . P.;

- organized familiarization of all applicants for work with the rules of behavior on the territory of the enterprise and basic safety rules, systematic training and testing of workers’ knowledge of safe work rules;

- providing workers with safety instructions and work areas with posters clearly showing dangerous places at work and measures to prevent accidents.

However, as a result of workers' neglect of safety precautions, accidents are possible. To protect yourself from an accident, you need to study safety rules and constantly follow them.

General industrial safety requirements.

1. When receiving a new (unfamiliar) job, require additional safety training from the foreman.

2.When doing work, you need to be attentive, not be distracted by extraneous activities and conversations, and not distract others.

3.On the territory of the plant (in the yard, building, on access roads) follow the following rules:

do not walk around other workshops of the enterprise unnecessarily;

be attentive to the signals given by crane operators of electric cranes and drivers of moving vehicles, and comply with them;

walk around loading and unloading areas and do not stand under a raised load;

do not walk in places not intended for passage, do not crawl under a stationary train and do not cross the path in front of moving vehicles;

do not cross conveyors and roller tables in undesignated places and do not crawl under them, do not enter fences without permission;

do not touch electrical equipment, terminals and electrical wires, general lighting fixtures and do not open electrical cabinet doors;

do not turn on or stop (except in emergency cases) machines, machines and mechanisms, the work of which is not entrusted to you by the administration of your workshop.

4. In case of injury or illness, stop work, notify the foreman and go to the first aid station.

Below are special safety requirements.

Before starting work:

1. Put your work clothes in order: fasten or wrap a wide elastic band around the sleeve cuffs; tuck in clothes so that there are no flapping ends of the clothes: remove the ends of a tie, scarf or scarf; Wear a tight-fitting headdress and tuck your hair under it.

2. Put on work shoes. Working in light shoes (slippers, sandals, sandals) is prohibited due to the possibility of injury to the feet from sharp and hot metal shavings.

3. Carefully inspect the workplace, put it in order, remove all objects that clutter and interfere with work. Arrange tools, devices, necessary materials and parts for work in a convenient and safe order for use. Make sure that the working tools and accessories are in good condition.

4. Check that the workplace is sufficiently illuminated and that the light does not blind the eyes.

5. If you need to use a portable electric lamp, check that the lamp has a protective mesh, that the cord and the insulating rubber tube are in good condition. The voltage of portable electric lamps should not exceed 36 V, which must be checked by the inscriptions on the panels and pantographs.

6. Make sure that the floor at the workplace is in full working order, without potholes, slippery surfaces, etc., that there are no exposed electrical wires nearby and that all dangerous places are fenced off.

7. When working with hoists or hoists, check their serviceability, raise the load to a small height and make sure the brakes, sling and chain are reliable.

8. When lifting and moving heavy loads, only one person should give signals to the crane operator.

9. Slinging (mooring) of the load must be reliable, using cleats (ropes or cables) of appropriate strength.

10. Before installing large-sized parts on a plate or on an assembly table, select installation and fastening devices (stands, spacers, squares, jacks, clamping strips, bolts, etc.) in advance.

11. When installing heavy parts, choose a position that allows you to process it with one or fewer installations.

12. Select the processing scheme and method in advance, take into account the convenience of changing tools and taking measurements.

During operation:

13. When sharpening tools on grinding wheels, be sure to wear safety glasses (if the wheel does not have a protective shield). If there is a protective screen, do not move it to the side, but use it for your own safety. Check whether the tool rest is installed well, bring it as close as possible to the grinding wheel, at a distance of 3-4 mm. When sharpening, stand not against the circle, but in a half turn towards it.

14. Monitor the serviceability of the guards of the rotating parts of the machines on which you have to work.

15. Do not remove shavings by hand, but use a wire hook.

16. All tool shops use compressed air with a pressure of 4 to 8 at. At this pressure, the air stream poses a great danger. Therefore, compressed air should be used with great care so that its stream does not accidentally hit the face and ears of the person using it or working nearby.

Safety precautions during installation work

Safe execution of procurement and installation work requires strict compliance by workers with safety regulations. Each employee must be knowledgeable and follow safe work practices. Only under this condition can accidents be prevented.

1. Occupational injuries occur due to a number of reasons:

improper organization of work, allowing people to work who have not received instructions on how to carry it out safely;

absence or malfunction of guards and safety devices;

faulty condition of tools and accessories;

improper maintenance of equipment and mechanisms;

neglect of safety precautions by workers.

2. When using lifting mechanisms, the following rules must be strictly observed: :

lifting mechanisms designed for a weight less than the weight of the load being lifted cannot be used;

lifting mechanisms must have properly functioning brakes, there must be no damage to gears and worm drives;

lifting mechanisms must be certified according to the appropriate procedure; operation of mechanisms without certification or with an overdue period for the next certification is prohibited;

When moving heavy objects, you must not be under the load, or in places where the load may end up in the event of a cable break.

3. When using locksmith tools, the following safety rules must be observed:

It is prohibited to use a tool that is faulty or not suitable for the work being performed;

the strikers of hammers and sledgehammers must have a smooth, slightly convex surface; and hammers and sledgehammers must be firmly mounted on the handles and secured to them with wedges;

Do not use chisels and bolts with broken heads;

Do not use files, hacksaws and screwdrivers without handles or with broken and poorly secured handles;

When working with pipe wrenches and wrenches, it is not allowed to put pieces of pipe on the handles of the wrenches and use metal pads under the jaws of the wrenches.

4. When using power tools, you must strictly follow the electrical safety rules:

It is unacceptable to work near live parts that are not protected by fences or casings;

metal casings, electric motors, electric drills, metal parts of starting devices, machine tools and other devices that may be energized in the event of insulation damage must be grounded;

for portable electric lamps, use a voltage no higher than 36 V;

wires conducting electric current to the welding machine and from the welding machine to the welding site must be insulated and protected from high temperatures and mechanical damage.

5. When carrying out welding work it is necessary:

cover your face with special shields in order to protect your eyes from the harmful effects of light and invisible ultraviolet and infrared radiation;

to eliminate the causes that contribute to the occurrence of fires during welding work, it is necessary to carefully protect wooden and other flammable parts and structures of buildings from ignition by sheet asbestos;

After completing welding work, you should carefully check the room and area where welding work was carried out and do not leave open flames or smoldering objects.

Fire safety briefings

A separate type of instruction—fire instruction—is devoted to the rules for preventing fires, as well as behavior during such an emergency. Fire safety training is mandatory for all organizations. The procedures are recorded in a fire safety log.

Fire safety briefings are similarly divided into:

- introductory;

- primary;

- repeated;

- unscheduled (when preventing a fire threat or an incident at another enterprise);

- targeted (when eliminating the consequences of a tragedy or before a mass event).

Approximate contents of fire safety instructions:

- rules for handling equipment that poses a fire risk, including open flames during hot work;

- signs of a starting fire;

- evacuation plan, PPE storage locations and fire safety system operating procedures;

- rules for handling a fire extinguisher, calling the fire department and other duties and recommendations in case of an emergency.

Electrical safety briefing

Another mandatory type of safety training is devoted to electrical safety. It depends on whether the employee is an electrical technician, that is, whether his responsibilities include installation, adjustment, maintenance and repair of electrical installations.

To find out whether the company has such employees (from a legal point of view), study Appendix No. 1 to Order No. 328n of the Ministry of Labor dated July 24, 2013. It lists the categories of workers and the conditions for assigning different electrical safety groups.

Responsibility for failure to comply with safety regulations

The most serious and terrible consequence may be causing serious harm to health or death to a person. In addition, failure to comply with instructions threatens material losses to the enterprise due to property damage. the main forms of liability will be presented , which primarily depend on how serious the consequences of the violation were.

- Disciplinary punishment (from a reprimand or reprimand to dismissal) must follow no later than one calendar month after the identified discrepancy.

- Material compensation may be demanded from an employee in the event of his illegal actions resulting in losses for the organization. The amount of compensation cannot exceed the amount of monthly salary, except in special cases. It is worth noting that the employee is not responsible for non-receipt of profit. This must be stated in the employment contract.

- Administrative penalties can be applied to officials and management of an organization in the event of their intentional actions leading to an offense.

- Criminal liability may follow if the actions of the guilty person show signs of a crime specified in Articles 143 and 215−219 of the Criminal Code of the Russian Federation.

In order to never face the above penalties, you must strictly follow the safety requirements. Often, employees are irresponsible when it comes to conducting briefings, consider it a pointless waste of time, and do not perceive the information properly. But under no circumstances should you neglect the rules that will help preserve life and health. No one is immune from accidents, natural disasters and similar emergencies. It is very important to understand what actions should be taken in such cases, and it is equally important to follow instructions that minimize the risks of threats to human life and health.

Instruction in educational institutions

Russians encounter safety issues not only at work, but also much earlier - in schools, technical schools and universities. Although some students are not yet capable citizens, parents and teachers bear responsibility for their health and life; from the age of 14 they also undergo instructions and sign for them.

List of safety instructions for students:

- rules of conduct in an establishment or institution;

- school evacuation plan;

- Fire safety;

- electrical safety;

- safety in public places, while traveling and at public events (targeted);

- rules of behavior in public transport;

- safety in the forest (target, before a hiking trip);

- safety on water bodies;

- behavior when threatened with a terrorist attack.

A safe workplace guarantees specialist health and comfortable working conditions.

Regulations on training at the enterprise

The Labor Code obliges employers to provide safety training. To streamline this work, it is recommended to issue a regulation setting out the order of briefings, their content, and the responsible persons. This document may be drawn up in free form in accordance with the procedure adopted by the enterprise.

Approximate contents of the Regulation:

- General characteristics of the document, its purpose and scope of action.

- Information about induction training - who conducts it, who is taking it, where it is conducted and what will be included.

- Similar points about initial, repeated, targeted and unscheduled briefings.

- Responsible employees, requirements for their qualifications, procedures for retraining and incentives.

- Final information - when it comes into force and how changes are made.

Regulations on safety briefings at enterprises: Regulations on the procedure for conducting occupational safety briefings

Regulations on labor protection specialist

Another important act that will streamline labor protection at an enterprise is the provision on the occupational safety specialist. This document, like the regulations, is drawn up in free form. Its approximate content:

- qualification requirements;

- specialist tasks;

- functions;

- rights;

- responsibilities;

- responsibility and subordination.

Download Regulations on a labor protection specialist: Regulations on a labor protection specialist

Why is it necessary to conduct training and periodic certification in labor protection?

The basis for the prevention of industrial injuries at an enterprise is the organization of training courses on basic labor protection requirements. Each employer, on the basis of Art. 212 of the Labor Code of the Russian Federation is obliged to create safe working conditions for personnel.

At the same time, each employee is obliged to strictly comply with established safety rules when performing their job duties. To do this, he must undergo the necessary training and instructions. It is important to take into account that the level of training must correspond to his profession, position, and the nature of the work performed.

TB magazines

The safety engineer is required not only to train workers, but also to document their familiarity with the rules. For this purpose, special journals are used, which indicate:

- the date of the;

- type of instruction;

- structural unit, department or workshop;

- instructor's name;

- signatures of the employee and instructor.

Buying a magazine on TB is not a problem; they are available in bookstores and stationery stores. Ready-made magazines are convenient because all the necessary columns are already lined up and signed. But it is not forbidden to make a magazine yourself, by creating a table in Word or Excel or by drawing a table by hand.

safety magazine: Induction magazine