Why is this plan needed?

Every employer is obliged to improve working conditions, create an optimal and safe working environment, in accordance with Art. 163 TK. An action plan to improve working conditions and safety is mandatory if significant funds are spent on occupational safety and the employer intends to use these costs to reduce contributions to the Social Insurance Fund for injuries. You can return up to 20% of the contributions paid for the previous year.

To do this, an application must be submitted to the Social Insurance Fund in any form before August 1. The program for improving working conditions for the current year will be the main document for the return of contributions for injuries for the previous year.

Main conclusions

Drawing up an action plan to improve working conditions is an important task, even if you do not apply to the Social Insurance Fund for reimbursement of labor protection expenses.

If you have been working as an occupational safety specialist in an organization for several years, then drawing up an action plan for the year will not be difficult; you know all the “sore spots” that need to be “treated.”

And if you have just started fulfilling your duties, then Order of the Ministry of Social Health Development No. 181n will be of great help to you; it contains all the main points that are suitable for both large companies and small businesses, which also could use occupational safety planning.

And if there is a point in carrying out activities, and there is one - creating safe working conditions, then there comes a moment when the amount of work performed turns into a quality result, the absence of fines and harm to the health of workers.

I wish you safe and efficient work!

If you have any questions after reading the note or you have something to add, give examples of effective application of the plan, write in the comments, it will be useful to other readers!

Regulatory basis for developing the plan

It is necessary to develop a plan to improve working conditions and safety in accordance with the following regulations:

- Art. 212, 226 TK. Art. 226 of the Labor Code of the Russian Federation. A manufacturing enterprise is required to spend at least 0.2% of production costs on improving working conditions and labor protection. Actually, the action plan determines where the allocated funds will be spent.

- A typical list of measures annually implemented by the employer to improve working conditions and safety and reduce occupational risks, approved by Order of the Ministry of Health and Social Development dated March 1, 2012 No. 181n. This document contains a list of activities that can be included in a plan to improve working conditions.

- GOST 12.0.230.1-2015. This state standard describes the occupational safety management system, planning and prevention.

Good and safe working conditions must be ensured:

- rational distribution of the load between the employee and the equipment;

- using reasonable standards of work and rest;

- improvement of technological processes and equipment;

- selection of professional personnel.

Full range of labor protection, civil defense and emergency services

Enter your phone number and I will calculate an estimate for your tasks. Enter without the eight. “Bureau of Ekaterina Vorontsova” – professional solutions to your problems: with high quality and on time!

Who develops measures to improve working conditions

In order to understand who is developing this document, you need to understand the scale of your organization, because for large companies special development groups are created, which are usually headed by the head of the labor protection department, while in small companies it is a labor protection specialist who prepares an action plan for improving working conditions and labor protection almost single-handedly.

And if your organization has a trade union committee, then all documents that affect the rights of workers must be approved by it.

How to draw up and what to include in an occupational safety action plan

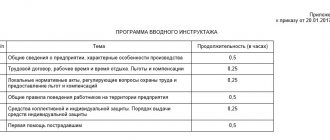

When drawing up a plan, as I said above, you need to take as a basis the standard plan of occupational safety measures, which was approved by order of the Ministry of Health and Social Development 181n.

It includes all the main measures to improve working conditions. You need to select all those that need to be carried out in your organization. In order not to cross out unnecessary things from the plan, you can take from the accounting department the amount for cost items and subaccounts for labor protection. This way you can identify activities that were carried out previously and include them in the current plan.

Next, you need to analyze the employees hired this year, as well as the number of jobs created, and the plan for the next year. This information will allow you to calculate the costs of unscheduled special education and training, training in training centers and medical examinations.

If the plan is drawn up by a specially created group, then at meetings problems in ensuring safe working conditions in the workplace are discussed; perhaps better quality PPE should be purchased or replaced with suitable ones. An order may also be prepared for the enterprise on the provision of information, labor safety issues, from the heads of departments.

In small organizations, everything is simpler; an occupational safety specialist goes to check departments, observes, communicates with managers and employees; from the latter, sometimes you can learn a lot of useful information that is not conveyed to specialists and management. Information is collected and conclusions are drawn, which are included in the action plan to improve labor safety conditions.

I advise you to raise an action plan to improve working conditions based on the results of the SOUT, if there were any, then the instructions of the State Labor Inspectorate, three-stage control logs and an analysis of the assessment of profrisks.

You can include whatever you want to improve working conditions, but it is not a fact that it will be approved by the employer. Therefore, when adding each item to the plan, you need to realistically assess the financial capabilities for each organization; in some, even purchasing PPE is difficult to accomplish.

And as a rule, any plan of organizational and technical measures to improve working conditions and safety always begins with more important measures, those that can lead to injury to workers, the development of occupational diseases and fines from supervisory authorities. And such as the acquisition of consumables: certificates, magazines and safety signs, include in the last points of the plan.

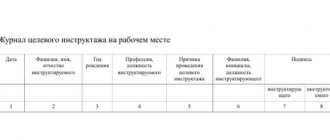

The plan is drawn up in the form of a table and must contain:

- Deadlines for completing activities.

- Responsible persons.

- Financing costs.

- Completion mark.

To answer the question: “For how long is the occupational safety action plan approved?”, you need to understand its final goal in addition to improving working conditions.

If you are also preparing it to understand your work for the year and further receive financial compensation from the Social Insurance Fund, then plan events for 1 year. And you need to start preparing in November - December.

If you want to build a quarterly strategy for the department for a quarter, or a month, this is acceptable, but in advance, 10 days or a week before the desired approval date.

You can take the approximate action plan to improve working conditions as a basis, adjusting the sample for your organization.

Monitoring the implementation of activities

It is necessary to monitor how measures to improve working conditions are carried out through regular inspections. And this should not be from time to time, but in advance of the reporting period.

After all, the head of a structural unit, also a human being, and in the hustle and bustle of endless work, may forget to prepare a memo on time for the purchase of new PPE.

A labor safety specialist is not an employer’s “Cerberus,” but a link in the organization that directs the work of the entire enterprise in a safe and efficient direction.

But if the head of the department completely refuses to implement the action plan to improve labor safety conditions, neither talk nor persuasion helps, you can prepare an order or memo setting the deadline for implementation.

If in this case there is no result, then the last resort remains - the employer, who is also responsible for the illegal actions of his employees during working hours.

What measures to improve working conditions can be included in the plan?

The list of all possible measures is in the above-mentioned order of the Ministry of Health and Social Development No. 181n. The list given here is not exhaustive:

- special assessment of working conditions (SOUT);

- modernization or purchase of more modern equipment;

- installation of equipment protection from external factors;

- improvement of alarm and warning systems;

- providing workers with special clothing and protective equipment (especially relevant in the current “coronavirus” realities);

- lighting of workplaces in accordance with standards;

- equipping production with first aid stations, or improving existing ones;

- arrangement of comfortable recreation areas;

- a separate dining room (or other room for eating), which is also relevant during a pandemic;

- installation of drinking water coolers;

- carrying out mandatory preventive medical examinations.

The list can be continued, everyone writes according to relevance and necessity. Especially, as already mentioned, it is necessary to pay attention to the explanations of Rospotrebnadzor on combating the spread of diseases. Based on the recommendations, you can make changes to the existing plan. By the way, doing this throughout the year is acceptable, especially if it benefits the employees.

A complete list of events is in the Order. It is advisory in nature and offers a classification into groups:

- organizational;

- sanitary;

- technical;

- are common;

- private;

- individual.

The organization may expand the list.

Activities within the framework of SOUT

The standard action plan for SOUTH is given in paragraph 2 of Appendix No. 1 to Order of the Ministry of Labor No. 33. The procedure for carrying out activities for SOUTH according to this document should contain:

- rules for determining the presence of harmful and dangerous conditions at a specific place of work;

- methodology for measuring detected negative factors;

- rules for classifying workplaces by classes of working conditions;

- requirements for processing the results of a special assessment using existing sample documents.

During the course of work, the presence of negative factors and the intensity of their impact are established not only during measurements at the workplace. Experts also study technological and operational documentation for the equipment used, design documents, data on the raw materials used, etc. Local regulatory documents of the enterprise, including job descriptions of company employees, are also subject to study. The results of the work performed are drawn up in the form of a report on the SOUT, which is approved by the customer.

Measures based on the results of a special assessment of working conditions

After completion of the special assessment work, the customer and the contractor must implement a number of operations that are mandatory in accordance with 426-FZ. Thus, for the expert organization that conducted the special labor assessment, the list of activities based on the results of a special assessment of working conditions includes:

- preparation of a report on the results of the work;

- submitting the report for approval to the customer;

- after approval - submission of information from the report to the federal information system for recording the results of the SOUT.

The list of actions that the customer must perform contains the following operations:

- approval of the submitted report or formation of justified claims to be eliminated. If the controversial situation between the parties is not resolved privately, the customer should contact the state labor inspection authorities or the court;

- informing company employees about the results of the special assessment;

- posting information about the results of work performed on the organization’s official website;

- formation of a system of measures based on the results of special environmental conditions aimed at reducing the negative impact of harmful factors on workers.

How to make a plan to improve working conditions

To create this plan, you can’t just sit down and write it on a piece of paper. The whole process will have to be divided into several stages:

- The head of the organization issues an order appointing a responsible working group and a person regulating the direction of its work.

- The group itself is created from employees of the enterprise.

- The group develops a draft action plan, the project is approved by management.

- An estimate is being developed in accordance with the approved plan.

To develop the plan, the group analyzes similar events in past years. If the plan is being drawn up for the first time, you can use the work of your colleagues and look for forms on the Internet. But it is better, of course, to turn to professionals who will take into account the specific features of your enterprise.

Attek company has been in the technology market for more than 20 years. We will not only prepare an action plan for you that complies with current legislation, but we will also train your staff. Yes, an integral part of ensuring safe work is regular testing of safety knowledge and training of your own specialists. In our training center you can train all categories of your employees in one place, including using remote technologies.

When drawing up an estimate according to the plan, it is necessary to take into account a number of important factors:

- The need for SOUT.

- The need to modernize equipment.

- Types of activities of the organization.

- The presence or absence of regulations from regulatory organizations (for example, GIT).

Who is on the working group to develop the plan?

The working group includes the management of the enterprise at all levels. There are three levels of system management:

- senior level - manager and his deputies, chief engineer, chief specialists;

- secondary - heads of structural units, mechanics and technologists;

- junior - foremen, foremen, foremen.

People are selected from among the managers of each unit to form a working group. The composition of the working group is approved by the leader by order.

Responsible persons

Occupational safety may become the responsibility of the direct employer, as well as a specialized specialist or employees of the relevant service. According to Article 217 of the Labor Code of the Russian Federation, companies with more than 50 employees must create a separate staff unit or department.

Only an employee who meets the current qualification requirements can be appointed as a labor safety inspector. The standards are set out in the professional standard for specialists in the field of labor protection and approved by order of the Ministry of Labor and Social Protection 524n dated August 4, 2014. To be allowed to work, an employee is sent for training and knowledge testing (it is possible to take a 40-hour course at a specialized training center).

If one specialist cannot cope with the task of protecting the life and health of enterprise personnel, a service of several people is created. The process is accompanied by making changes to the staffing table, developing job descriptions and adjusting the regulations on the labor protection service.

For reference: the required number of employees of this profile is determined taking into account the total number of personnel of the enterprise, the level of danger and the severity of work processes. Additionally, you must be guided by the Intersectoral headcount standards approved by Resolution of the Ministry of Labor No. 10 of January 22, 2001.

Control of labor protection measures is entrusted to the chief engineer, general or technical director. However, overall responsibility for the work of the appointed inspectors rests with the head of the relevant service.

Where to get a sample plan

The standard form of the specified plan for improving labor conditions and safety is proposed in the specified order of the Ministry of Health and Social Development No. 181n. The most important thing that should be there is information about the financing of the planned events.

The plan should also contain information about the persons responsible for its implementation at the enterprise. As a rule, these are department heads and specialists appointed responsible in the labor protection regulations.

The deadlines for the implementation of the plan, both as a whole and for individual activities, must be indicated.

Principles for developing a labor protection system

Only a specialist with at least several years of experience can complete a task of such complexity. Beginners can make critical mistakes that can ultimately lead to serious consequences.

When organizing labor protection, you need to rely on current legislation, including:

- Federal Law No. 52 of March 30, 1999, establishing the conditions for ensuring the sanitary and epidemiological well-being of citizens;

- Federal Law No. 323 of November 21, 2011, which sets out the basics of protecting public health in the Russian Federation;

- Federal Law No. 116 of July 21, 1997, concerning industrial safety issues at hazardous production facilities;

- Federal Law No. 426 of December 28, 2013, which provides the concepts, principles of formation and other provisions on SOUT;

- Resolution of the Ministry of Labor of Russia No. 14 of February 8, 2000 with recommendations for the creation and operation of an occupational safety service.

Plan approval

A prepared and properly developed draft plan to improve working conditions and safety is approved by all departments. Optionally, an act is drawn up with the participation of a trade union (this is not necessary, but is used in large companies).

When the plan is approved, it may be adjusted “on the spot”. After this, the action plan can be formalized as a section of a collective agreement or contract. All those responsible for its implementation are included in it. The plan is drawn up in a final document and signed by the manager. Then comes approval by order for the enterprise.

After it has gone through all stages of approval, large companies or at the request of a trade union may require its publication on the company website. For this, as well as for making ongoing changes, it is recommended to appoint a separate responsible person (this can be a manager).